Innovations and Best Practices in 2025

In 2025, the corporate hardware sector is undergoing a significant transformation, driven by the adoption of new technologies, advanced methodologies, and a growing focus on efficiency and sustainability. Businesses require increasingly powerful, durable, and easy-to-maintain devices, while assembly and repair techniques are evolving to meet the demands of a rapidly changing market.

In this article, we will explore the latest innovations and best practices for hardware assembly and maintenance, highlighting the most effective solutions to ensure reliability, security, and sustainability.

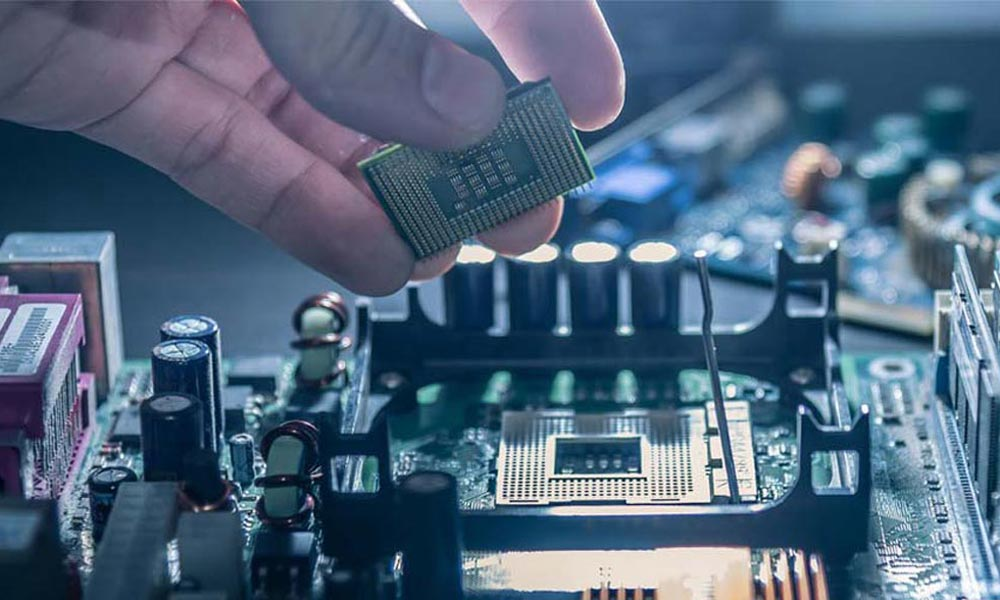

Innovations in Hardware Assembly

Hardware assembly is no longer a static, manual process; it is evolving with the integration of advanced technologies.

1. Automation and Robotics

Automation is revolutionizing hardware assembly. Robots and AI-powered mechanical arms improve precision, reduce errors, speed up production, and ensure consistent quality.

2. Innovative Materials

New materials, such as high-strength lightweight alloys, biodegradable components, and advanced polymers, are enhancing hardware durability and sustainability. Additionally, the growing use of modular materials simplifies future repairs and upgrades.

3. Modular Assembly

The adoption of modular components allows companies to upgrade and replace parts quickly and cost-effectively. This approach reduces waste and promotes a circular economy, contributing to environmental sustainability.

4. 3D Printing for Custom Components

3D printing is becoming increasingly relevant in hardware assembly. Companies can print components on demand, reducing supply chain delays and customizing devices to their specific needs.

Repair and Maintenance: Best Practices for 2025

Hardware repairs are no longer lengthy and complex, thanks to the use of advanced tools and innovative methodologies.

1. AI-Powered Predictive Diagnostics

AI plays a crucial role in preventive maintenance. Smart sensors monitor hardware conditions in real time, predicting potential failures before they occur and enabling proactive interventions.

2. Remote Maintenance and Augmented Reality (AR)

With augmented reality, technicians can view real-time repair instructions through AR headsets, reducing service times and improving efficiency. Additionally, remote maintenance allows IT specialists to diagnose and fix problems without being physically present, cutting support costs.

3. Advanced Repair Tools

New tools, such as high-resolution digital microscopes, laser soldering stations, and infrared desoldering systems, enable more precise and less invasive repairs, extending hardware lifespan.

4. Refurbished Components and Recycling

The use of high-quality refurbished components is becoming more common, lowering costs and minimizing environmental impact. Companies are increasingly investing in material recycling, supporting a circular economy.

Benefits of New Technologies for Businesses

The adoption of these innovations in hardware assembly and repair offers numerous advantages for companies:

- Reduced Downtime: Predictive maintenance and rapid repairs minimize device downtime.

- Cost Optimization: Modular and refurbished components reduce upgrade and repair expenses.

- Improved Sustainability: Recyclable materials, circular economy practices, and efficient processes lower environmental impact.

- Enhanced Security: Advanced diagnostics and preventive maintenance reduce the risk of critical failures and data loss.

In 2025, corporate hardware assembly and repair are driven by automation, artificial intelligence, and sustainability. Companies that adopt these innovations not only improve operational efficiency but also gain a competitive advantage in a market increasingly focused on technology and waste reduction.

Investing in advanced technologies for hardware maintenance and assembly is no longer optional—it is essential to ensure business continuity, security, and long-term sustainability.